Liquids containing dissolved gases can reduce the effectiveness of the ultrasonic pressure wave propagation. When subjecting liquids with dissolved gases to ultrasonic energy, the dissolved gases may come out of solution and form bubbles that dampen the effectiveness of the ultrasonic power. Thus degassing is a necessary procedure prior to starting any ultrasonic process.

Ultrasonic energy can be used to aid in degassing the liquid as follows: when subjecting liquids to ultrasonic power, the sound waves that propagate from the ultrasonic radiating surface into the liquid produce an alternating high-pressure and low-pressure cycles. During the low-pressure cycle, the ultrasonic waves can create small vacuum bubbles or voids in the liquid. The large number of small bubbles generates a high total bubble surface area. The bubbles are also well distributed in the liquid. Dissolved gas migrates into these vacuum (low pressure) bubbles via the large surface area and increases the size of the bubbles. The ultrasonic waves assist in the touching and coalescence of adjacent bubbles leading to an accelerated growth and rise of the bubbles, thereby effectively degassing the liquid. The ultrasonic waves will also help to shake bubbles off vessel surfaces and will force smaller bubbles resting below the liquid surface to rise through and release the entrapped gas to the environment.

While the ultrasonic power itself can aid in degassing liquids by reducing the level of dissolved gases in liquids, in many cases it is necessary to reduce and maintain the level of dissolved gases below what ultrasonic degassing can accomplish. Moreover, it may be desirable to degas in a continuous mode rather than a batch mode as ultrasonic degassing requires. In these situations membrane degassing is ideal for continuously degassing liquids to very low levels of dissolved gases down to the parts per million (ppm) levels. PermSelect® silicone membrane modules are ideal for continuously degassing liquids in a simple and economical way.

- How to Degas Liquids using PermSelect® membrane modules?

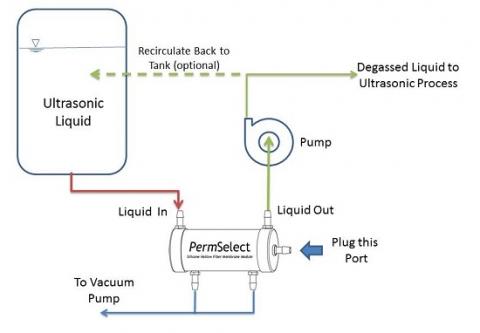

Degassing liquids using PermSelect® membrane modules is straightforward as illustrated in the figure below. Liquid with dissolved gases is contained in a reservoir, or a continuous feed is supplied upstream from the membrane module. A pump may be placed in the circuit (upstream or downstream from the membrane module) if needed to provide a required flow rate through the system. The simplest method to degas a liquid is to use straight vacuum to remove all dissolved gases from the liquid. As shown in the figure below, liquid is supplied to one side of the silicone membrane through feed port of the PermSelect® membrane module. Vacuum provided from a vacuum pump is applied to the opposite side of the membrane through the permeate ports of the module. The dissolved gases in the liquid will permeate across the membrane toward the vacuum, thereby effectively degassing the liquid. Extracted gases flow toward the vacuum pump and the degassed liquid exits through the exit port.

Ultrasonic Degassing of Liquids using PermSelect® Membrane Modules

Liquid degassing can be accomplished continuously with a single pass through the membrane module or with multiple passes by recirculating the fluid through a reservoir. The choice will depend on the system design, the capacity of the module to remove gases, and the required level of degassing. Other considerations include liquid-membrane compatibility, and the system fluid pressures. Please view the silicone chemical compatibility chart as an initial substance compatibility guide. Depending on your system pressure requirements, a reversal of liquid flow and vacuum (a lumen side liquid flow) may be required. The maximum recommended trans-membrane pressure (TMP) for shell side liquid flow is 15 psi. So if your system exceeds this TMP then a lumen side liquid flow is recommended up to 45 psi TMP.

Order membrane modules and gas exchangers online > 25% off for first time buyers. Click here for more details.

Contact an applications engineer, or call +1 (734) 769-1066 to discuss your particular liquid degassing needs.

MedArray provides its PermSelect® membrane modules for liquid degassing directly to researchers, and to industry through original equipment manufacturers (OEM’s) who are interested in integrating degassing solutions in their ultrasonic equipment. We can also customize membrane modules to your specific application. Contact us to discuss your custom application.