Silicone (PDMS) has a very high permeability to CO2 compared to nitrogen and oxygen thus allowing for CO2 membrane separation from combustion and flue gas; the difference in permeability facilitates the transfer of CO2 preferentially over N2 and O2, thus enabling the removal of CO2 from combustion and flue gas.

Membrane separation processes are inherently cleaner and more environmentally friendly compared to other methods for CO2 separations. When implemented properly, CO2 membrane separation methods have no VOC emissions, no hazardous chemicals are necessary, little or no water usage is required, and no fossil fuels are consumed.

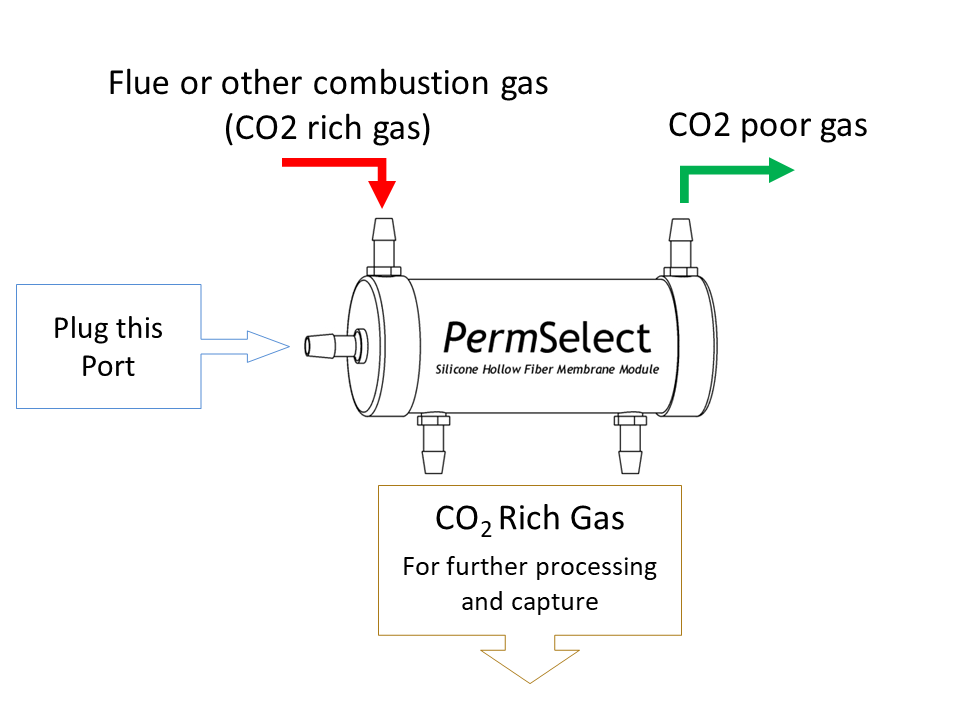

How to remove CO2 from combustion and flue gas using silicone membrane separation?

Removal of CO2 is simple and straightforward as shown in the figure below. The pressurized feed gas (flue gas or combustion gas) is supplied to one side of the membrane though the feed port of the PermSelect gas exchanger, and depending on the feed pressure, a vacuum to the opposite side of the membrane may be necessary at the permeate ports. The CO2 with higher permeability compared to N2 and O2 in the combustion gas will permeate the membrane much faster than the N2 and O2, thereby stripping the feed gas from much of its CO2. A CO2 rich gas will exit at the permeate port, which can be fed to a second membrane stage to obtain higher purity CO2, or to other processing for eventual CO2 capture.

Our silicone hollow fiber membrane packaging provides many advantages over the spiral wound format, especially in low feed pressure applications (< 100 psi), including up to ten times higher membrane area density per volume, no porous substrate to impede gas transfer or limit compatibility, and substantially lower cost per unit area.

Due to the current size of our PermSelect® membrane gas exchangers (<10 m2), they can only be used for slip-stream testing in low feed pressure applications (<45 psi) such as in lab environments. While we currently provide modules for preliminary laboratory testing, we are actively seeking strategic partners with well established presence in this field to collaborate on scaling-up and developing optimized products incorporating our membrane technology. If your organization is interested in providing methane separating solutions using our patented technology, Contact us or call us at +1 (734) 769-1066 x21 to discuss opportunities.